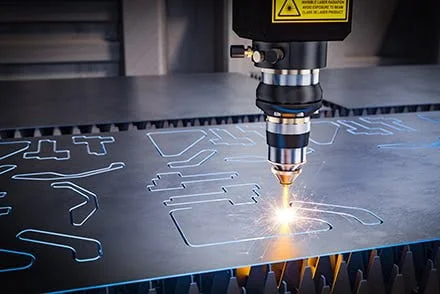

Laser Metal Cutting with Onsite Nitrogen Generators

Laser cutting is a process that utilizes a laser to cut materials. Nitrogen gas is often used in this process to improve the quality of the cut. Nitrogen use in laser cutting is a well-known process for creating beautiful stainless steel and aluminum. With the latest technology in super-fast motion systems, it is now necessary to use nitrogen cutting assist gas even on mild steel to get the full value from the laser. The benefits of using nitrogen with lasers in metalworking are many. The use of onsite nitrogen generators such as those offered by NOVAIR can make this process even more efficient and cost-effective.

Nitrogen (0.001- 0.01 vol.% O2 residual) | Nitrogen Generators For Use with Laser Cutting The benefits of nitrogen use in laser cutting are well known, especially for processing stainless steel and aluminum. Today, there are many new super-fast motion systems, with rapid acceleration and deceleration. It is necessary to use nitrogen cutting assist gas, even on mild steel, to get the full value from the laser cutting machine. |

Advantages of Using Nitrogen in Laser Cutting

The advantages of using nitrogen are numerous. Here are some of them:

- Nitrogen can improve the quality of the cut, especially when working with stainless steel and aluminum. It can create a cleaner cut edge and help reduce dross and oxidation.

- Nitrogen can also help speed up the cutting process, resulting in faster production times and greater efficiency.

- The use of nitrogen can also help extend the life of the laser cutting machine. It reduces the amount of wear and tear on the equipment.

Benefits of Using Nitrogen in Laser Cutting

Onsite nitrogen generators, such as NOVAIR’s offerings, provide several additional benefits when working with lasers to make great metal shapes:

- Onsite nitrogen generators can provide a continuous supply of high-purity nitrogen gas, which can help ensure consistent and high-quality cuts.

- By producing nitrogen gas onsite, manufacturers can save money on the cost of purchasing nitrogen gas cylinders. This totally removes the need to transport them to the facility, improving safety overall.

- Onsite nitrogen generators can also provide greater flexibility in terms of production scheduling. Manufacturers can produce nitrogen gas as needed, adjusting the flow rate to match the demands of the laser cutting process.

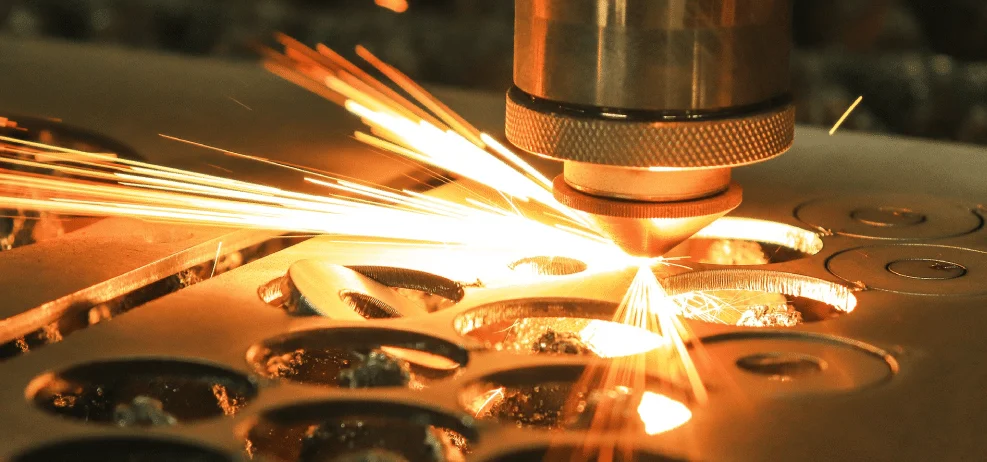

Problems That Can Occur When Not Using Nitrogen

It may be easy to consider foregoing the use of nitrogen in metalworking. However, often customers will visibly see the difference. Metal cuts are noticeably duller without N2. The metal can experience a number of other issues that become clearly apparent to end-purchasers of the finished metal product. This makes it seems like the metal was produced without much time, effort, and capital expense. Quite simply, when it comes to working with metal, nobody is happy when the cut doesn’t look good!

When nitrogen is not used, several problems can arise that significantly affect the quality and efficiency of the cutting process. One major issue is oxidation. Using air or oxygen instead of nitrogen can lead to oxidation of the cut edges. This can result in a rougher and darker finish. Oxidation then requires additional post-processing, such as grinding or polishing to achieve a clean and smooth edge. This ultimately increases time and labor costs. Additionally, the presence of oxygen can cause slag formation on the cut edges, which is more pronounced in thicker materials. It further complicates the process and reduces productivity to manually remove this slag. In contrast, nitrogen helps to produce a cleaner cut by preventing oxidation and reducing slag formation.

Nitrogen Can Negatively Affect Cutting Speed

Cutting speed can also be adversely affected. Nitrogen provides a more stable cutting environment, allowing for faster processing speeds. When air or oxygen is used, the cutting speed might be reduced, impacting overall production efficiency. This is particularly critical in high-volume manufacturing where time is a key factor. Moreover, using compressed air or oxygen can lead to increased thermal stress on the material. This can potentially cause warping or distortion, especially in thinner sheets. This affects the dimensional accuracy and structural integrity of the final product. Being an inert gas, Nitrogen minimizes these thermal stresses, ensuring better dimensional stability and overall quality.

Nitrogen Can be Cost-Effective and Give High-Quality Results

Nitrogen gas in laser cutting is essential for ensuring high-quality designs and efficient production times. Not using nitrogen in laser cutting can lead to oxidation, increased slag, reduced cutting speed, and thermal stress. This can detrimentally impact the quality, efficiency, and cost-effectiveness of the cutting process. Studies show that under appropriate conditions, with nitrogen as assisting gas, solid-state lasers achieve considerably higher cutting speed and surface quality than CO2 lasers. (For example, see: Experimental Investigation of Industrial Laser Cutting: The Effect of the Material Selection and the Process Parameters on the Kerf Quality, by Silvio Genna, Erica Menna, et al). By utilizing onsite N2 generators, manufacturers can achieve even greater efficiency and cost savings while maintaining the consistency and quality of their laser cutting processes. NOVAIR has several onsite nitrogen generators that provide reliable and effective solutions for continuous high-purity nitrogen gas supply for laser cutting needs.

About NOVAIR

Worldwide leading manufacturer of on-site gas production systems, NOVAIR is the founder of the Green Oxygen concept and the vision that decentralized on-site medical oxygen production with the only low-carbon way to supply oxygen to hospitals. With over 45 years of experience manufacturing high-quality medical and industrial gas generating equipment, and with high-tech R&D centers in France, USA and Italy, NOVAIR definitively leads the world in innovative on-site gas production by adsorption systems.

Headquartered in France, NOVAIR operates in over 150 countries and has installed thousands of gas generators around the planet, supplying daily life-saving medical oxygen to hundreds of thousands of patients the world over. NOVAIR also provides industrial oxygen and nitrogen that enhances the effectiveness of scores of industries through a broad range of applications and market segments.

Contact us to learn more.